Hyundai i-30: Brake System / Stop Lamp Switch

Components and components location

| Components |

| 1. Brake member

assembly 2. Stop lamp switch 3. Return spring |

4. Brake pedal

arm assembly 5. Brake pedal pad |

Schematic diagrams

| Schematic Diagram |

| System Circuit Diagram |

| Terminal Function |

|

Teminal |

Description |

|

1 |

IGN1 |

|

2 |

BS |

|

3 |

- |

|

4 |

B+ |

|

5 |

Stop Lamp |

|

6 |

Ground |

Troubleshooting

| Troubleshooting |

| 1. |

Part diagnosis

|

| 2. |

Symptom diagnosis

|

| 3. |

Stop lamp switch system diagnosis

SSEM : Stop Signal Electronic Module

|

| 4. |

Refer to DTC guide when the related DTC codes are displayed.

|

Repair procedures

| Adjustment |

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 2. |

Remove the lower crash pad.

(Refer to Body - "Crash Pad")

|

| 3. |

Confirm the gap between stop lamp switch and bracket.

|

| 4. |

If the gap between stop lamp switch and bracket is not 1.0-2.0mm (0.04-0.08in),

check the mounting clip and other part of around stop lamp.

|

| 5. |

If there is normal, remove the stop lamp switch and then install again.

|

| Inspection |

1. Fuse Inspection

Mount the test fuse to the switch fuse and relay fuse part to confirm a normal

joint fit.

2. Diagnostic tool Data Analysis

| 1. |

Analyze diagnostic tool data and confirm if there is anything wrong

with the stop lamp switch.

|

3. Inspection Of Connector By Each Part

Check to see whether or not each connector has been damaged, or terminal surge,

or incomplete connection has taken place

[Engine Room Junction Box]

[ABS/VDC Control Module]

4. Inspect The Stop Lamp Circuit

Connect probe to each terminal wire and confirm oscilloscope waveform.

[Stop Lamp Switch Input / Output]

[Oscilloscope Waveform Screen]

| Removal |

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 2. |

Remove the crash pad lower panel.

(Refer to Body - "Crash Pad Lower Panel")

|

| 3. |

Disconnect the stop lamp switch connector (A).

|

| 4. |

Pull the locking plate (A) as indicated by the arrow.

|

| 5. |

Turn stop lamp switch 45° counterclockwise and remove it.

|

| 6. |

Inspect a removed stop lamp switch along the below procedures.

|

| Installation |

| 1. |

Fix the brake pedal arm and insert fully the stop lamp switch as hiding

contact part.

|

| 2. |

After inserting, turn the stop switch (A) 45° clockwise, and then assemble

locking plate by pushing.

|

| 3. |

Confirm the gap between stop lamp switch and bracket.

|

| 4. |

Connect the stop lamp switch connector.

|

| 5. |

Install the crash pad lower panel.

(Refer to Body - "Crash Pad Lower Panel")

|

Rear Disc Brake

Rear Disc Brake

Components and components location

Components

[With EPB]

1. Caliper body

2. Guide rod pin

3. Guide rod pin boot

4...

Other information:

Hyundai i30 (PD) 2018-2025 Service Manual: Steering Column Shroud Panel

Components and components location Component Location 1. Steering column shroud lower panel 2. Steering column shroud upper panel Repair procedures Replacement [Steering column shroud upper panel] • Put on gloves to prevent hand injuries...

Hyundai i30 (PD) 2018-2025 Service Manual: Blower Motor

Repair procedures Inspection 1. Connect the battery voltage and check the blower motor rotation. 2. If the blower motor does not operate well, substitute with a known-good blower motor and check for proper operation...

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- EPB malfunction indicator

- Cruise control

- To activate the ISG system

- New on site

- Most important about car

Tailgate

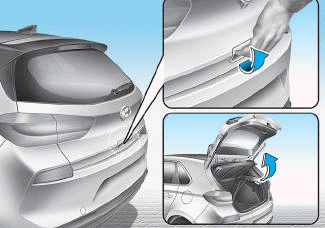

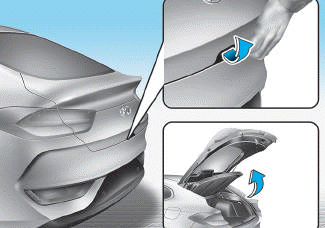

Opening the tailgate

■ 5 Door, Wagon

■ Fastback

Copyright © 2025 www.hi30.net