Hyundai i-30: Fuel Delivery System / High Pressure Fuel Pump

Specifications

Items

|

Specification

|

High Pressure Fuel Line

|

bar

|

20 - 350

|

MPa

|

2 - 35

|

kgf/cm²

|

20.4 - 356.9

|

psi

|

290.1 - 5076.3

|

Repair procedures

| •

|

In case of removing the high pressure fuel pump, high pressure

fuel pipe, delivery pipe, and injector, there may be injury

caused by leakage of the high pressure fuel. So don’t do any

repair work right after engine stops.

|

|

|

1. |

Turn the ignition switch OFF and disconnect the battery (-) terminal.

|

|

2. |

Release the residual pressure in fuel line.

(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel

Line")

|

|

3. |

Remove the engine cover.

(Refer to Engine Mechanical System - "Engine Cover")

|

|

4. |

Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

|

5. |

Disconnect the high pressure fuel pump connector (A) and then disconnect

the fuel feed tube quick-connector (B).

|

• |

Open the clamp cover (A) before disconnecting the quick

connector (if the clip is applied).

|

|

|

• |

When removing the quick-connector by using a clip removing

tool (A), be careful not to damage the plastic clip

(B).

|

|

• |

If the clip is damaged, fuel line leakage may occur

due to poor connection.

|

|

|

|

6. |

Remove the high pressure fuel pipe.

(Refer to Fuel Delivery System - "Delivery Pipe")

|

|

7. |

Remove the high pressure fuel pump (A).

|

Tightening Torque :

12.7 - 14.7 N.m (1.3 - 1.5 kgf.m, 9.4 - 10.8 lb-ft)

|

|

• |

Unscrew in turn the two bolts in small steps (0.5 turns).

If one of the two bolts is fully unscrewed while the

other is installed, the housing surface of the cylinder

head may get broken due to the tension on the pump spring.

|

|

|

| •

|

Before installing the high pressure fuel pump, position the

roller tappet in the lowest position by rotating the crankshaft.

Otherwise the installation bolts may break due to the tension

on the pump spring.

|

| •

|

Keep away from foreign materials when assembling.

|

| •

|

Do not reuse the high pressure fuel pipe.

|

| •

|

When tightening the installation bolts of the high pressure

fuel pump, pretighten the bolts by hand, and then fully tighten

in turns in small steps (0.5 turns).

|

| •

|

Install the component to the specified torques.

|

| •

|

First, pretighten the fasteners by hand until they are not fastened

anymore in order to have them inserted in place, and then using

a torque wrench, fully tighten them to the specified torque.

If the bolts or nuts are not tightened in a straight line with

the mating bolt holes or fittings, fuel leakage may occur due

to broken threads.

|

| •

|

Note that internal damage may occur when the component is dropped.

In this case, use it after inspecting.

|

| •

|

Apply engine oil to the O-ring (A) of the high pressure fuel

pump, the roller tappet (B), and the protrusion (C). Also apply

engine oil to the groove on the location where the protrusion

(C) is installed.

|

|

|

1. |

Install in the reverse order of removal.

|

• |

Use the special service tool [SST No. : 09314-3Q100

or 09314-27130] to install the high pressure fuel pipe.

|

|

|

Repair procedures

Removal

•

In case of removing the high pressure fuel pump, high pressure

fuel pipe, delivery pipe, and injector, there may be injury

caused by leakage of the high pressure fuel...

Other information:

Type A

If the light bulb does not operate, we

recommend that you have the vehicle

checked by a HYUNDAI authorised

repairer.

Type B

1.Remove the lamp assembly from

the vehicle by prying the lens and

pulling the assembly out.

2.Disconnect the bulb electrical connector...

Climate control air filter

This filter is installed behind the

glove box. It filters the dust or other

pollutants that enter the vehicle

through the heating and air conditioning

system.

We recommend that the climate control

air filter be replaced by a

HYUNDAI authorised repairer according

to the maintenance schedule...

Categories

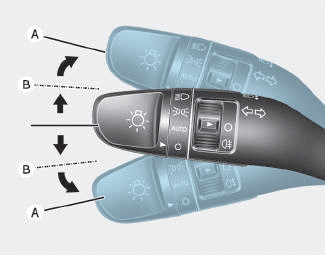

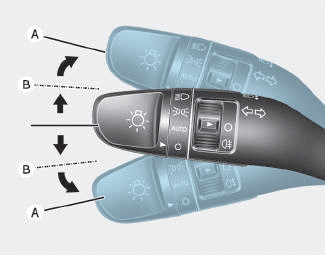

To signal a turn, push down on the

lever for a left turn or up for a right

turn in position (A). To signal a lane

change, move the turn signal lever

slightly and hold it in position (B).The

lever will return to the OFF position

when released or when the turn is

completed.

read more

Delivery Pipe

Delivery Pipe