Hyundai i-30: Engine Control System / Oil Pressure & Oil Temperature Sensor (OPTS)

Hyundai i30 (PD) 2018-2025 Service Manual / Engine Control / Fuel System / Engine Control System / Oil Pressure & Oil Temperature Sensor (OPTS)

Description and operation

| Description |

It generates the oil pressure and temperature information (output voltage) to

control the pump operation proportional control valve in variable oil pump system.

It measures the oil pressure and temperature discharged from the oil pump and

transmits the pressure information to ECM. The ECM controls the proportional

control valve to regularly keep the discharged pressure depending on RPM.

Specifications

| Specification |

Oil Pressure Sensor

▷ Type : Capacitive type

|

Pressure |

Output Voltage (V) |

|

|

bar |

[MPa (kgf/cm², psi)] |

[Vref=5V] |

|

0.5 |

0.05 (0.5, 7.2) |

0.3 |

|

1 |

0.1 (1.0, 14.5) |

0.5 |

|

6 |

0.6 (6.1, 87.0) |

2.5 |

|

11 |

1.1 (11.2, 159.5) |

4.5 |

Oil Temperature Sensor

▷ Type : Thermistor type

|

Temperature [°C, (°F)] |

Resistance (kΩ) |

|

-40 (-40) |

125.5 - 136.7 |

|

-30 (-22) |

93.3 - 104.7 |

|

-20 (-4) |

63.9 - 71.2 |

|

-10 (14) |

41.8 - 46.5 |

|

0 (32) |

26.8 - 30.1 |

|

10 (50) |

17.2 - 19.2 |

|

20 (68) |

11.1 - 12.5 |

|

25 (77) |

9.0 - 10.1 |

|

30 (86) |

7.4 - 8.3 |

|

40 (104) |

4.9 - 5.5 |

|

50 (122) |

3.3 - 3.8 |

|

60 (140) |

2.3 - 2.6 |

|

70 (158) |

1.6 - 1.8 |

|

80 (176) |

1.2 - 1.3 |

|

90 (194) |

0.86 - 0.97 |

|

100 (212) |

0.64 - 0.72 |

|

110 (230) |

0.48 - 0.54 |

|

120 (248) |

0.37 - 0.41 |

|

130 (266) |

0.28 - 0.32 |

|

140 (284) |

0.22 - 0.25 |

|

150 (302) |

0.17 - 0.2 |

|

160 (320) |

0.14 - 0.17 |

Schematic diagrams

| Circuit Diagram |

Harness Connector

Repair procedures

| Inspection |

| 1. |

Switch "OFF" the ignition.

|

| 2. |

Remove the CVVT oil temperature sensor.

(Refer to - "Removal")

|

| 3. |

After immersing the thermistor of the sensor into engine coolant, measure

resistance between the OTS terminals 1 and 2.

|

| 4. |

Check that the resistance is within the specification.

|

|||||||||||||||||||||||||||||

| Removal |

| 1. |

Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

|

| 2. |

Lift the vehicle.

|

| 3. |

Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 4. |

Remove the oil pressure & oil temperature sensor (A) after disconnect

the oil pressure & oil temperature sensor connector.

|

| Installation |

|

| 1. |

Install in the reverse order of removal.

|

Rail Pressure Sensor (RPS)

Rail Pressure Sensor (RPS)

Description and operation

Description

Rail Pressure Sensor (RPS) is installed on the delivery pipe and measures the

instantaneous fuel pressure in the delivery pipe...

Injector

Injector

Description and operation

Description

The GDI injector is similar to a standard injector, but sprays fuel at a much

higher pressure directly into the combustion chamber and has a swirl disc to

get the fuel swirling as it exits the nozzle...

Other information:

Hyundai i30 (PD) 2018-2025 Owner's Manual: System malfunction

DAW (Driver Attention Warning) system When the "Check DAW (Driver Attention Warning) system" warning message appears, the system is not working properly. In this case, we recommend that you have the vehicle inspected by a HYUNDAI authorised repairer...

Hyundai i30 (PD) 2018-2025 Service Manual: Emergency Signal System

Description and operation Description Introduction of Quick Brake Warning System (ESS) In case of quick brake by driver, the brake lamp or turn signal is blinked to warn against the vehicle at rear. 1. Basic function (Blinking the brake lamp/emergency lamp) – Operation condition : In case of quick brake or operation of ABS above in a certain speed – Releasing condition : In case of stopping the quick brake or releasing the ABS operation 2...

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- Trip computer

- LKA system operation

- Recommended lubricants and capacities

- New on site

- Most important about car

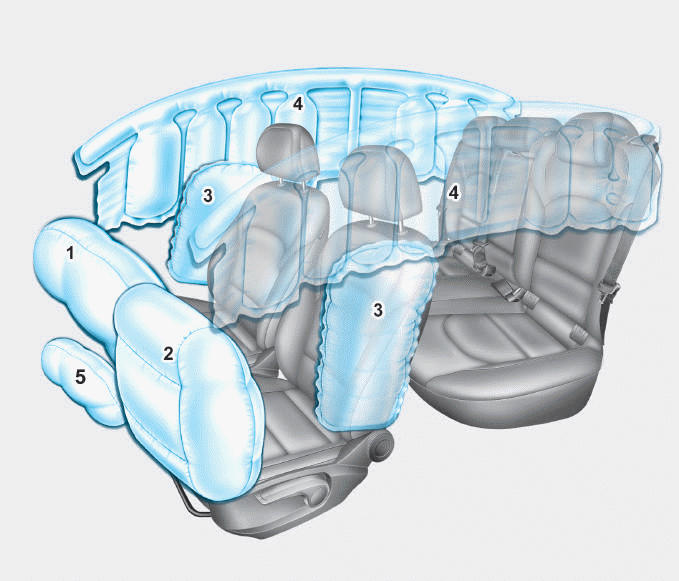

Air bag - supplemental restraint system

1. Driver’s front air bag

2. Passenger’s front air bag

3. Side air bag*

4. Curtain air bag*

5. Knee air bag*

6. Front passenger air bag ON/OFF

switch

Copyright © 2025 www.hi30.net