Hyundai i-30: Front View Camera System / Repair procedures

|

When you need variant coding:

| –

|

Replace Front View Camera with a new one

|

※ EOL Variant Coding and calibration required for new replacement

|

Front View Camera Variant Coding

Front view camera variant coding makes it possible to operate functions for

each vehicle type. If the variant coding differs from the vehicle specification,

the "variant coding error" DTC is displayed.

|

1. |

Procedure for coding variants

|

(1) |

You should read the specification information for the front

view camera that is installed in the vehicle before replacing

it with a new front view camera.

|

|

(2) |

Connect the cable of Diagnostic tool to the data link connector

in driver side crash pad lower panel, and turn on the Diagnostic

tool.

|

|

(3) |

Select the 'S/W Management' and 'Car model'.

|

|

(4) |

Select "System Identification".

|

|

(5) |

Select "Variant Coding".

|

|

(6) |

Enter the value of the specification read in procedure(4) in

the new front view camera.

|

|

| Service Point Target Auto

Calibration (SPTAC) |

When you need calibration:

| – |

Front view camera is removed and mounted

|

| – |

Replace front view camera with a new one

|

| – |

Windshield glass changed

|

| – |

front view camera coupler of the windshield glass is deformed

|

Service Point Target Auto Calibration (SPTAC)

Front view camera SPTAC provides the method for the service technician to calibrate

the camera by aligning the calibration target (SST: 09890-3V100) with the vehicle

on a level ground.

If the calibration is not completed within the specified tolerance front view

camera "System Out of Calibration" DTC is indicated.

|

1. |

Method for Correct Alignment of Calibration Target

In order to complete the calibration of the front view camera successfully,

install the calibration target as follows:

| –

|

Install the target (SST: 09890-3V100) vertical to the ground

and from the camera referring to the below tolerance angle.

|

|

The tolerance ± 1° for the left and right gradient is very important

and is sensitive to the flatness of the ground.

Install the compensator vertically using the Level Laser (SST:

09958-3T060 or 09964-C1200).

Arrange the Level Laser (A) on the center of the vehicle by

installing it on the roof center above the vehicle's front windshield

(same for both short and long distance calibrations) .

Have the laser illuminate starting from the roof center and

to all the way to the center of the target, passing through

the emblem center.

The level laser must be set to 'ON' and the holding (locking)

function is not used.

|

|

Target is mounted to rigid backer material to maintain flatness

requirements.

|

– |

Target has reflective (not faded or poorly painted)

markings that are unlike from lane features.

|

|

– |

Target is 30 cm wide and 100 cm tall.

|

|

– |

Mounting area must NOT have cross hatch patterns or

textual markings near the target.

|

|

– |

Target should be well lit for optimal performance using

non-fluctuating illumination. There shall be no continuous

shadows cast on the target.

|

|

– |

The light should be directed toward the target front

and the target front should be brighter than the target

rear and target.

|

|

|

|

2. |

Service Point Target Auto Calibration(SPTAC) Procedure

| 1) |

It is recommended to check vehicle toe-in and tire pressure

levels to ensure proper alignment of the camera to the "world"

before proceeding with calibration. The vehicle to run the calibration

routine is to be at nominal production loading capacity.

|

| 2) |

Windshield must be clean and silk-screen checked so that there

is no blockage of the camera.

|

| 3) |

Service technician connects the diagnostic connector and starts

the vehicle. The front view camera should not be activated by

pressing the switch.

|

| 4) |

The service calibration routine may not run correctly if any

system level fault is active.

|

| 5) |

If working with a replacement ECU: the service technician initiates

the SPTAC Reset configuration.

|

| 6) |

Service technician either aligns the vehicle to the target or

the target to the vehicle.

a. Locate the bottom of the target 90cm from the ground (max.

tolerance: 1cm).

b. Locate so that the central axis of the target and the central

axis of the vehicle match (max. tolerance: 3cm).

c. Locate the short-distance target (A) so that it adheres by

0cm (B) to the bumper front (max. tolerance: 5cm).

d. The location of the long-distance target (C) is 100cm (D)

before the bumper (max. tolerance: 5cm).

|

| 7) |

Select Camera Calibration under Option of Global Diagnosis System

(Diagnostic tool).

|

| 8) |

The technician should complete the short-distance calibration

after checking the target location and "OK" message on the Diagnostic

tool.

|

| 9) |

The technician should complete the long-distance calibration

after checking the target location and "OK" message on the Diagnostic

tool (conduct the calibration twice: short and long distances).

|

If the distance 100 ± 5 cm (39.4 ± 2 inch) is different

from the distance indicated on the Diagnostic tool,

calibrate it according to the value indicated on the

Diagnostic tool.

|

|

|

Test Drive

| –

|

Be sure to perform test drive to check for normal operation

after performing calibration.

|

| –

|

Drive on straight road (of longer than 500 m) with 2 white or

yellow lane marks at speed of over 40mph(60km/h), and check

for the alert as you intentionally steer close to the lane mark.

|

| –

|

LKA operates properly if the lane mark segment space is less

than 8 m.

|

| –

|

Perform test drive on car-only road or on a highway.

|

|

| •

|

The LKA is a system to prevent lane departure and assist steering.

In any case, do not rely on the steering assist system, and

the driver must take the necessary precautions to determine

safety matters.

|

| –

|

Driver is responsible for being aware of surroundings and steering

the vehicle for safe driving practices.

|

| –

|

Do not tinted window or attaching any types of coatings and

accessories.

|

| –

|

Do not allow any water or liquid to contact the front view camera.

|

| –

|

Do not remove the front view camera parts and do not damage

the front view camera by a strong impact.

|

| –

|

Do not put objects that reflect light on the crash pad.

|

| –

|

Excessive noise can make the LKA alarm sound unheard.

|

|

High Beam Asisst (HBA)

|

The system may not operate normally in the below conditions.

| –

|

When the light from the oncoming or front vehicle is not detected

because of lamp damage, hidden from sight, etc.

|

| –

|

When the lamp of the oncoming or front vehicle is covered with

dust, snow or water.

|

| –

|

When the light from the oncoming or front vehicle is not detected

because of exhaust fume, smoke, fog, snow, etc.

|

| –

|

When the front window is covered with foreign matters such as

ice, dust, fog, or is damaged.

|

| –

|

When there is a similar shape lamp with the front vehicle’s

lamps.

|

| –

|

When it is hard to see because of fog, heavy rain or snow.

|

| –

|

When the headlamp is not repaired or replaced at an authorized

dealer.

|

| –

|

When headlamp aiming is not properly adjusted.

|

| –

|

When driving on a narrow curved road or rough road.

|

| –

|

When driving downhill or uphill.

|

| –

|

When only part of the vehicle in front is visible on a crossroad

or curved road.

|

| –

|

When there is a traffic light, reflecting sign, flashing sign

or mirror.

|

| –

|

When the road conditions are bad such as being wet or covered

with snow.

|

| –

|

When the front vehicle’s headlamps are off but the fog lamps

on.

|

| –

|

When a vehicle suddenly appears from a curve.

|

| –

|

When the vehicle is tilted from a flat tire or being towed.

|

|

Forward Collision-avoidance Assist (FCA)

|

The Forward Collision-avoidance Assist (FCA) may not operate properly

in the following conditions, when

| –

|

The sight of the objects in front is narrow (etc. motorcycle).

|

| –

|

The car in front takes a round turn at the roundabout.

|

| –

|

The car in front is a special-featured vehicle such as a special

vehicle or a truck carrying a specific type of luggage or a

trailer.

|

| –

|

The rear part of the car in front is not properly identified.

(ex it is turned or overturned).

|

|

Lane Keeping Assist (LKA) / Lane Following Assist (LFA)

|

The LKA/LFA may not activate properly in the following conditions.

| –

|

It is difficult to distinguish the lane from the road due to

dust built up on the lane.

|

| –

|

It is difficult to distinguish the color of the lane line from

the road.

|

| –

|

There is a mark that looks like a lane line near the line.

|

| –

|

The lane line is indistinct or damaged.

|

| –

|

The number of lanes increases or decreases or the lane lines

are crossing (driving through toll plaza, toll gate, road merging

or dividing area, etc.).

|

| –

|

There are more than two lane lines.

|

| –

|

The lane is very wide or narrow.

|

| –

|

The lane is not visible due to snow, rain, stain, a puddle or

other factors.

|

| –

|

Shadows of objects (median strip, guard rail, noise barriers,

etc.) surrounding the road are casted on the lane.

|

| –

|

The lane is congested or it is replaced by a structure in a

construction area.

|

| –

|

There is a indication on the road surface such as crosswalk

or road signs.

|

| –

|

The lane inside the tunnel is covered with dust or oil.

|

| –

|

There is a boundary structure.

|

| –

|

Driving on the bus-only lane or on the left/right of the lane.

|

| –

|

The lane suddenly disappears at certain locations such as at

the intersection.

|

|

Description and Operation

Blcok Diagram

•

This system monitors the driving situations through the radar

and the camera...

Schematic diagrams

Circuit Diagram

Repair procedures

Removal

1.

Disconnect the negative (-) battery terminal...

Other information:

The child safety lock is provided to

help prevent children seated in the

rear from accidentally opening the

rear doors. The rear door safety locks

should be used whenever children

are in the vehicle.

The child safety lock is located on

the edge of each rear door...

If the engine stalls whilst driving

Reduce your speed gradually,

keeping a straight line. Move cautiously

off the road to a safe place.

Turn on your hazard warning flasher.

Try to start the engine again. If your

vehicle will not start, we recommend

that you contact a HYUNDAI

authorised repairer...

Categories

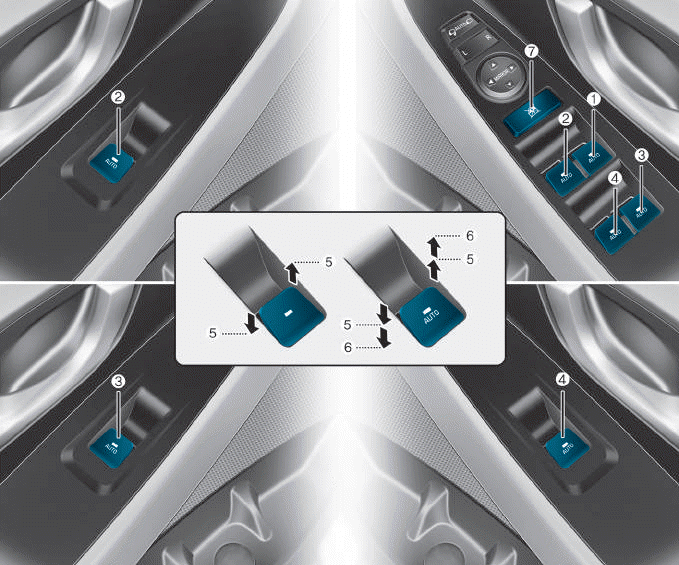

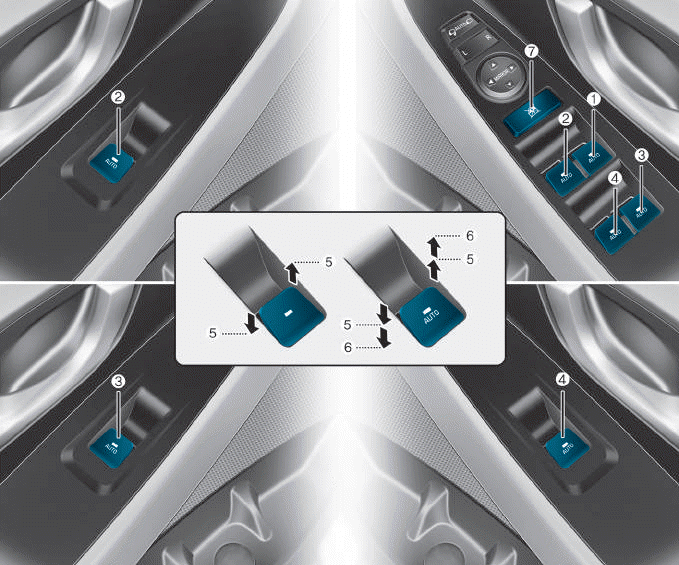

(1) Driver’s door power window

switch

(2) Front passenger’s door power

window switch

(3) Rear door (right) power window

switch

(4) Rear door (left) power window

switch

(5) Window opening and closing

(6) Automatic power window

(7) Power window lock switch

read more

Description and operation

Description and operation Front View Camera Unit

Front View Camera Unit