Hyundai i-30: Cylinder Head Assembly / CVVD Assembly

Hyundai i30 (PD) 2018-2025 Service Manual / Engine Mechanical System / Cylinder Head Assembly / CVVD Assembly

Description and operation

| Description |

CVVD (Continuous Variable Valve Duration) System is a device to control the

optimum open and close timing according to the driving mode by changing the

valve opening section.

It is composed of cam shaft, CVVD assembly, and CVVD acatuator.

The valve opening time operates in proportion to the rpm of control shaft.

| Operation Principle |

[CVVD System Operating Mode]

| Optimum Valve Timing by Engine Load |

Repair procedures

| Removal |

| 1. |

Disconnect the battery negative terminal.

|

| 2. |

Remove the timming chain.

|

| 3. |

Remove the intake CVVT assembly (A) and exhaust CVVT assembly (B).

|

| 4. |

ve the camshaft front bearing cap (A) and camshaft bearing caps (B).

|

| 5. |

Remove the CVVD assembly.

Use the CVVD fixture

Do not use the CVVD fixture

|

| 6. |

Remove the exhaust camshaft (A).

|

| Installation |

| 1. |

Install the exhaust camshaft (A).

|

| 2. |

Install the CVVD assembly (A).

|

| 3. |

Install the intake CVVT assembly (A) and exhaust CVVT assembly (B).

|

| 4. |

Install the front camshaft bearing cap and the camshaft bearing caps

as following method with specified torque.

|

| 5. |

Install the other parts in the reverse order of removal.

|

CVVT & Camshaft

CVVT & Camshaft

Description and operation

Description

The continuous variable valve timing (CVVT) system advances or retards the opening

of an intake or exhaust valve according to the ECM signals that are determined

based on engine RPM and load...

Cylinder Head

Cylinder Head

Repair procedures

Removal

1.

Remove the engine cover.

(Refer to Engine and Transaxle Assembly - "Engine Cover")

2...

Other information:

Hyundai i30 (PD) 2018-2025 Service Manual: Troubleshooting

Troubleshooting Symptom Suspect area Remedy Engine misfire with abnormal internal lower engine noises. Worn crankshaft bearings. Loose or damaged engine drive plate. Replace the crankshaft and bearings as required...

Hyundai i30 (PD) 2018-2025 Owner's Manual: Engine Stop/Start button positions

-..

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- Auto door lock/unlock features

- Engine compartment

- Theft-alarm system

- New on site

- Most important about car

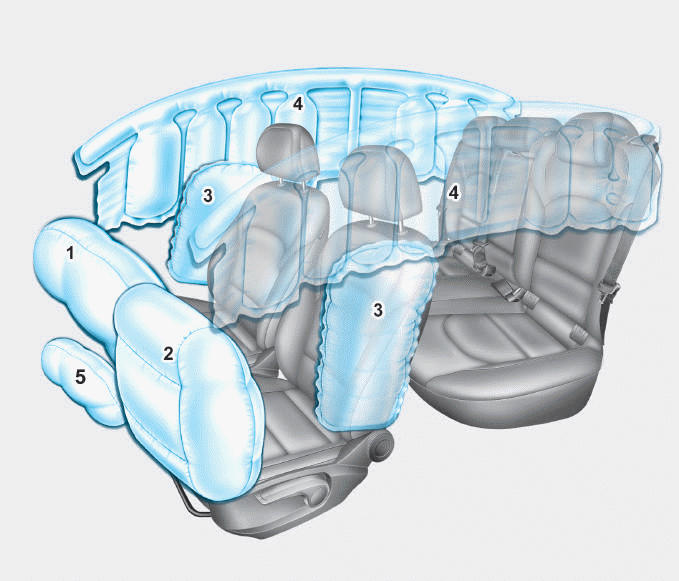

Air bag - supplemental restraint system

1. Driver’s front air bag

2. Passenger’s front air bag

3. Side air bag*

4. Curtain air bag*

5. Knee air bag*

6. Front passenger air bag ON/OFF

switch

Copyright © 2025 www.hi30.net